makerdad

New Project: Workout Timer

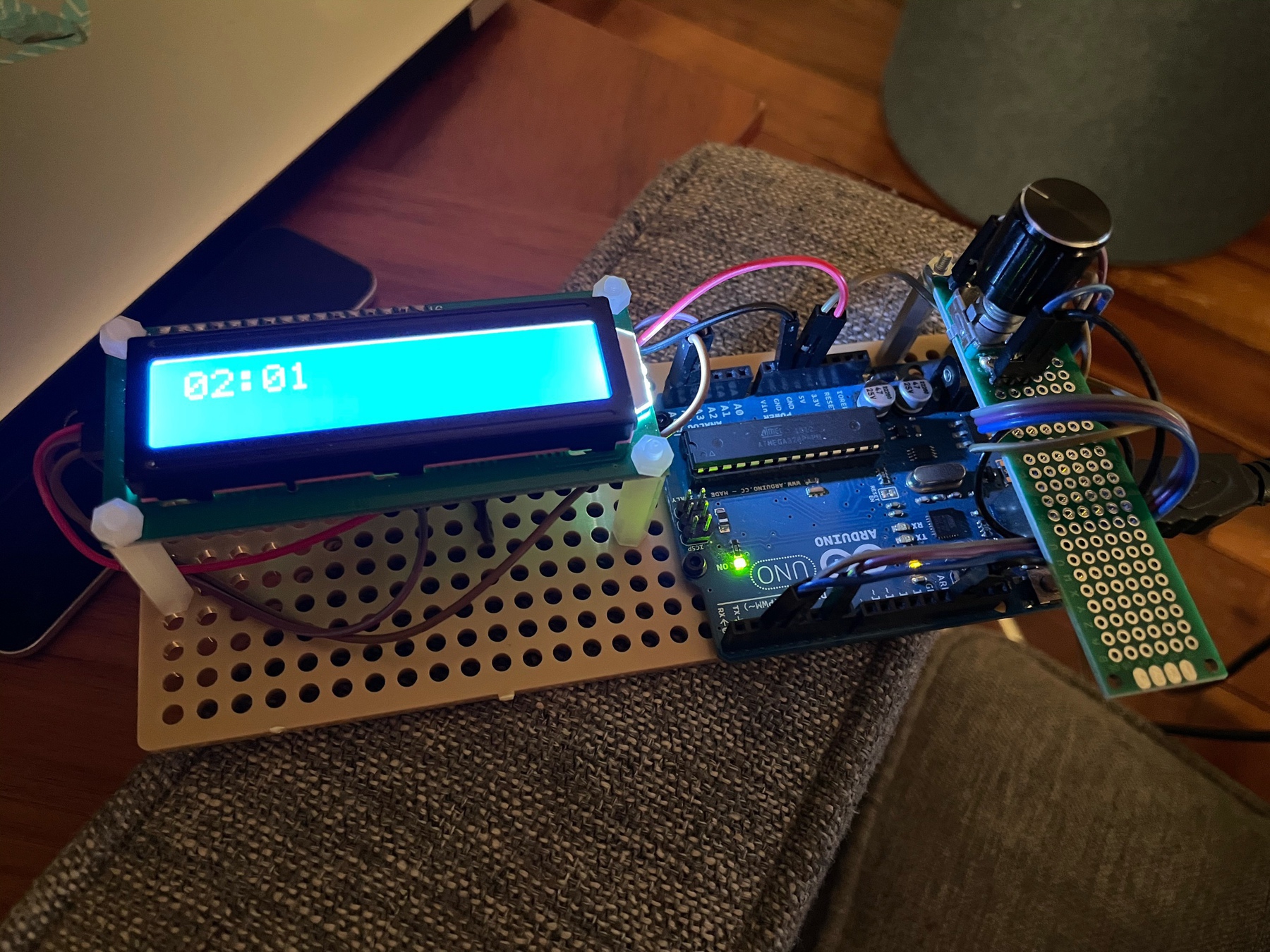

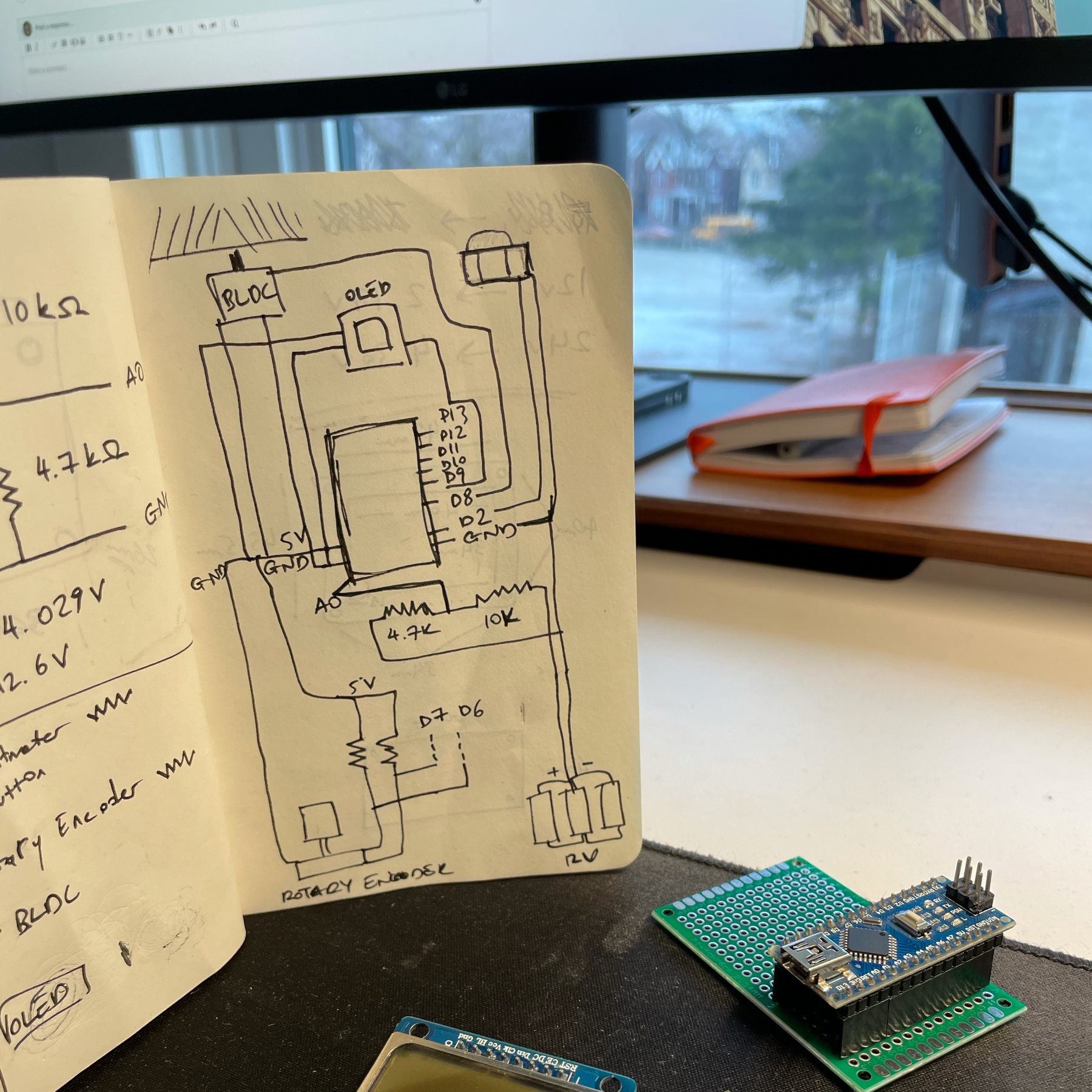

Started work on a little side project: A workout timer. I need a simple timer during morning workouts and this is a good challenge for it.

Requirements and problems to solve:

- Smooth rotary encoder feedback (suprisingly hard)

- Large numbers on LCD

- Object oriented menu system

- Battery powered and rechargeable

Built a prototype board with LCD, encoder and Arduino for easy testing. Encoder implementation with interrupt pins already working nicely. Next step: OOB menu system.

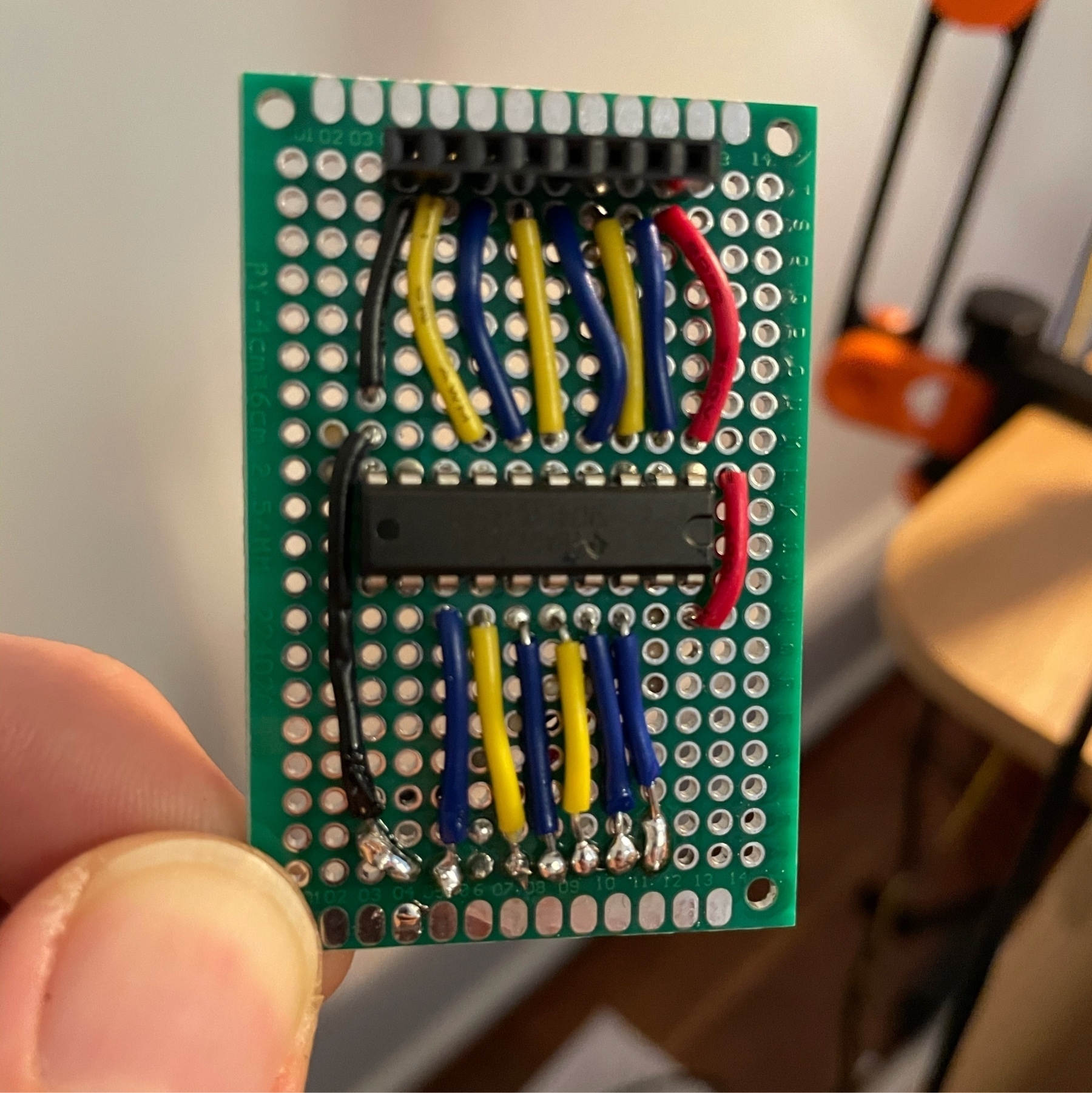

Still have a long way to go, but I’m proud of the improvements in my soldering. Lots of lessons learned:

- Lower heat is better (30W)

- Clean the board and tip

- Use flux for connections

- Utilize both sides of PCB

- Check connectivity with multimeter

Decided to make the jump and learn Fusion 360. I have been using Blender and as much as I like it, it’s not built for prototype design. I had a visceral reaction to Fusion’s horrible interface but even after a few hours I can see the advantages.

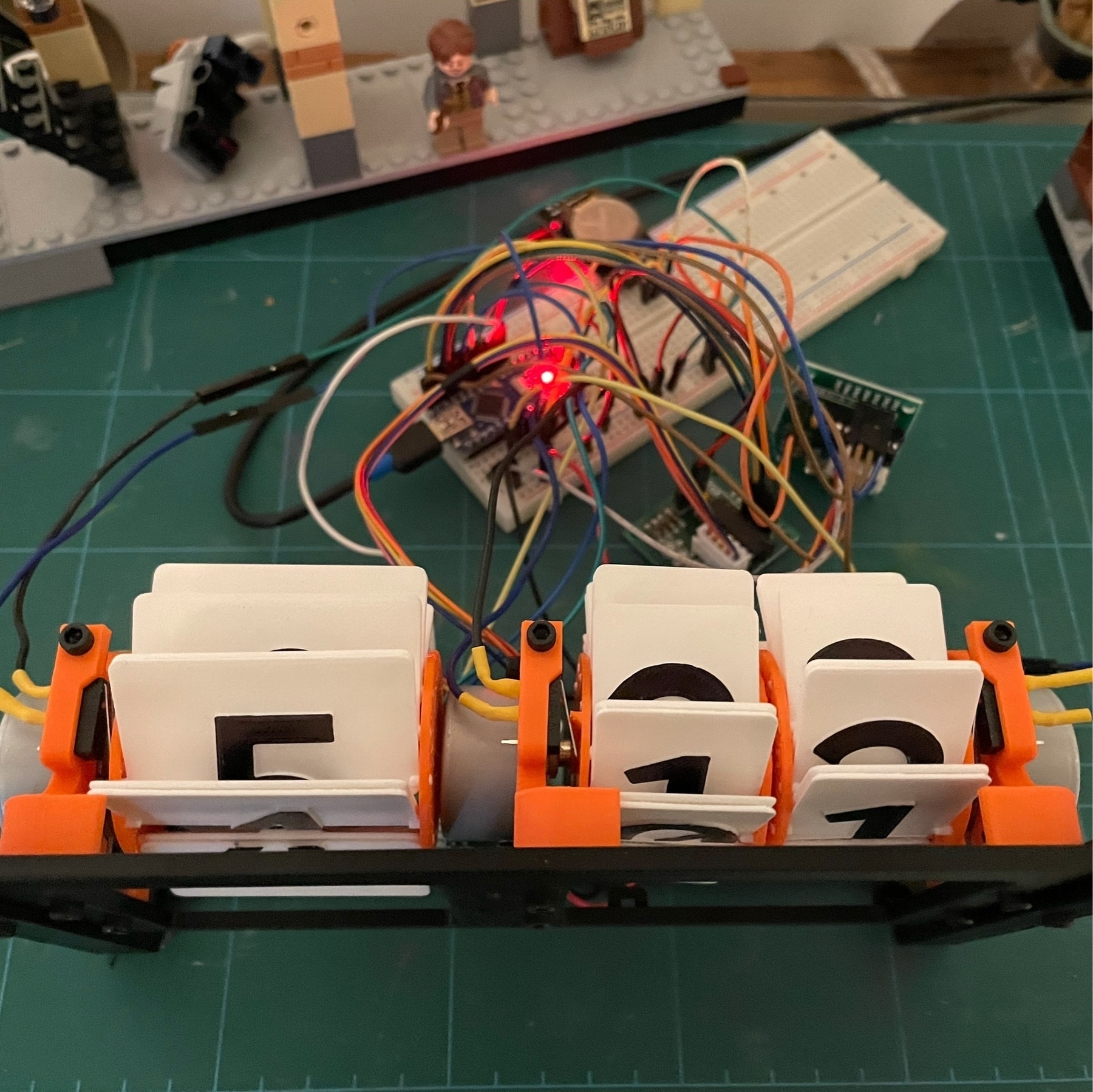

After several minor adjustments, got the first successful version of the flipclock running well. Electronics is a mess that needs to be organized on a PCB, but pretty happy with the results!

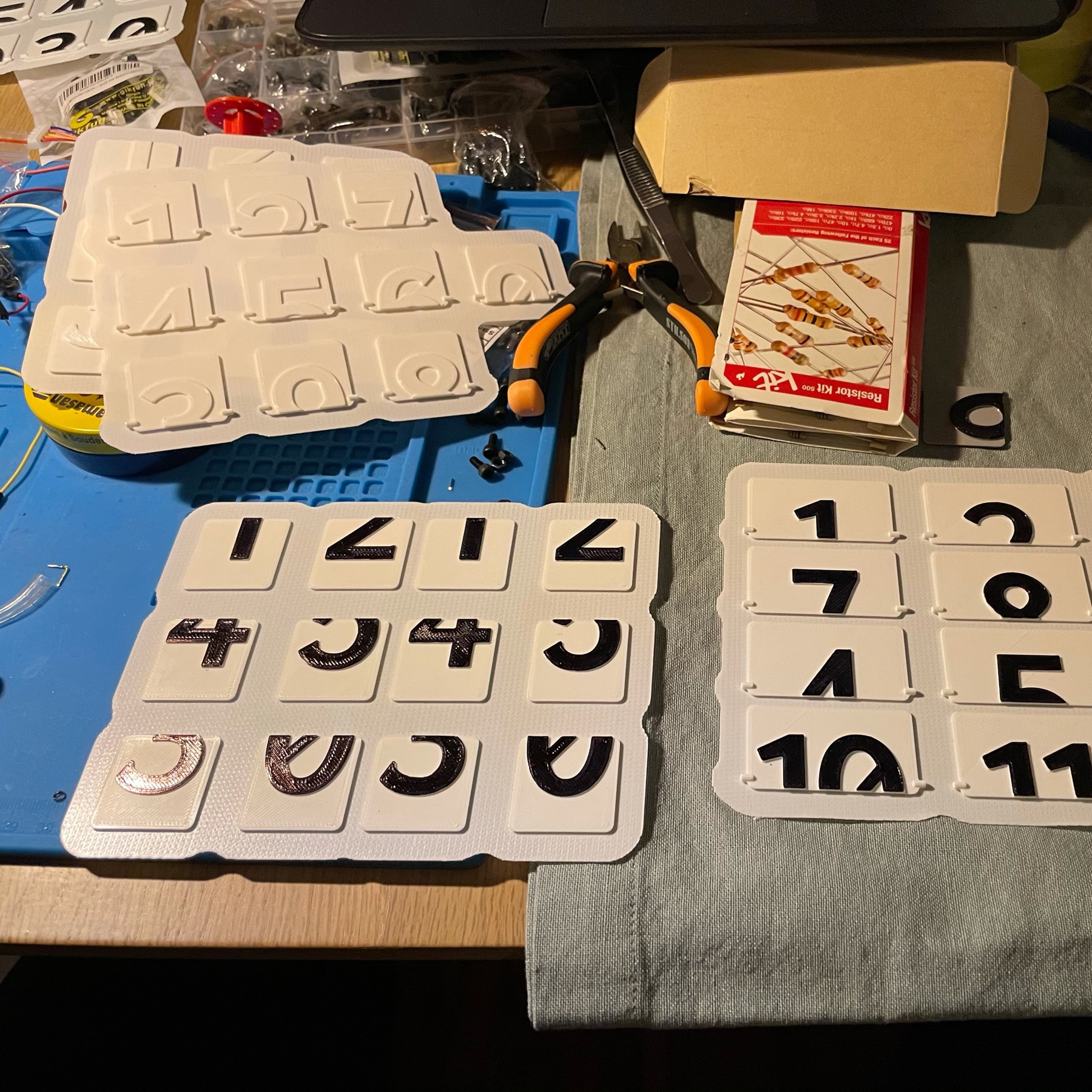

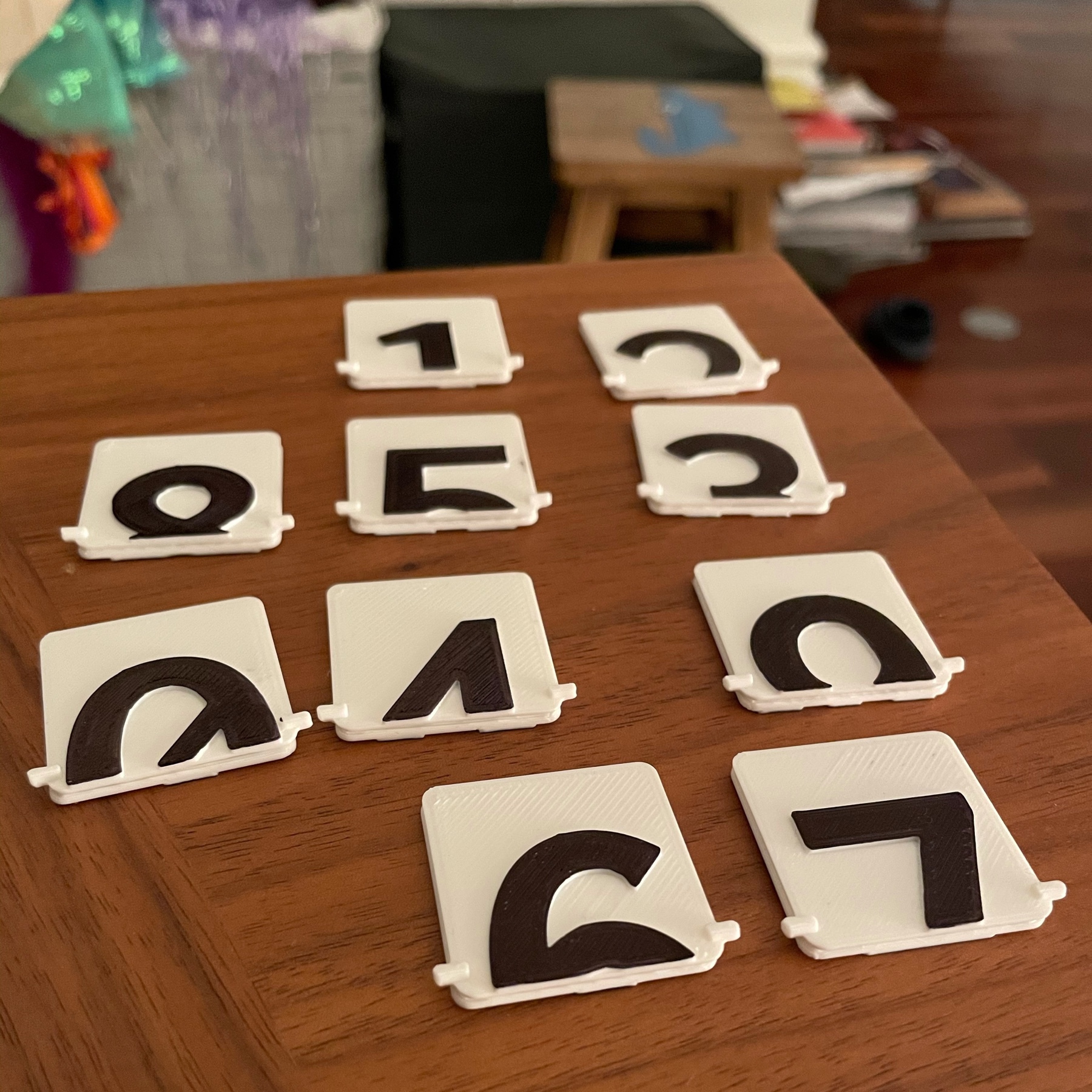

Had some issues with the flipclock. New digits look great, but they didn’t fit in the original spools, since they are thicker. Had to design and print new spools, which meant the motor holder screws got in the way. Hoping to resolve all of this tonight.

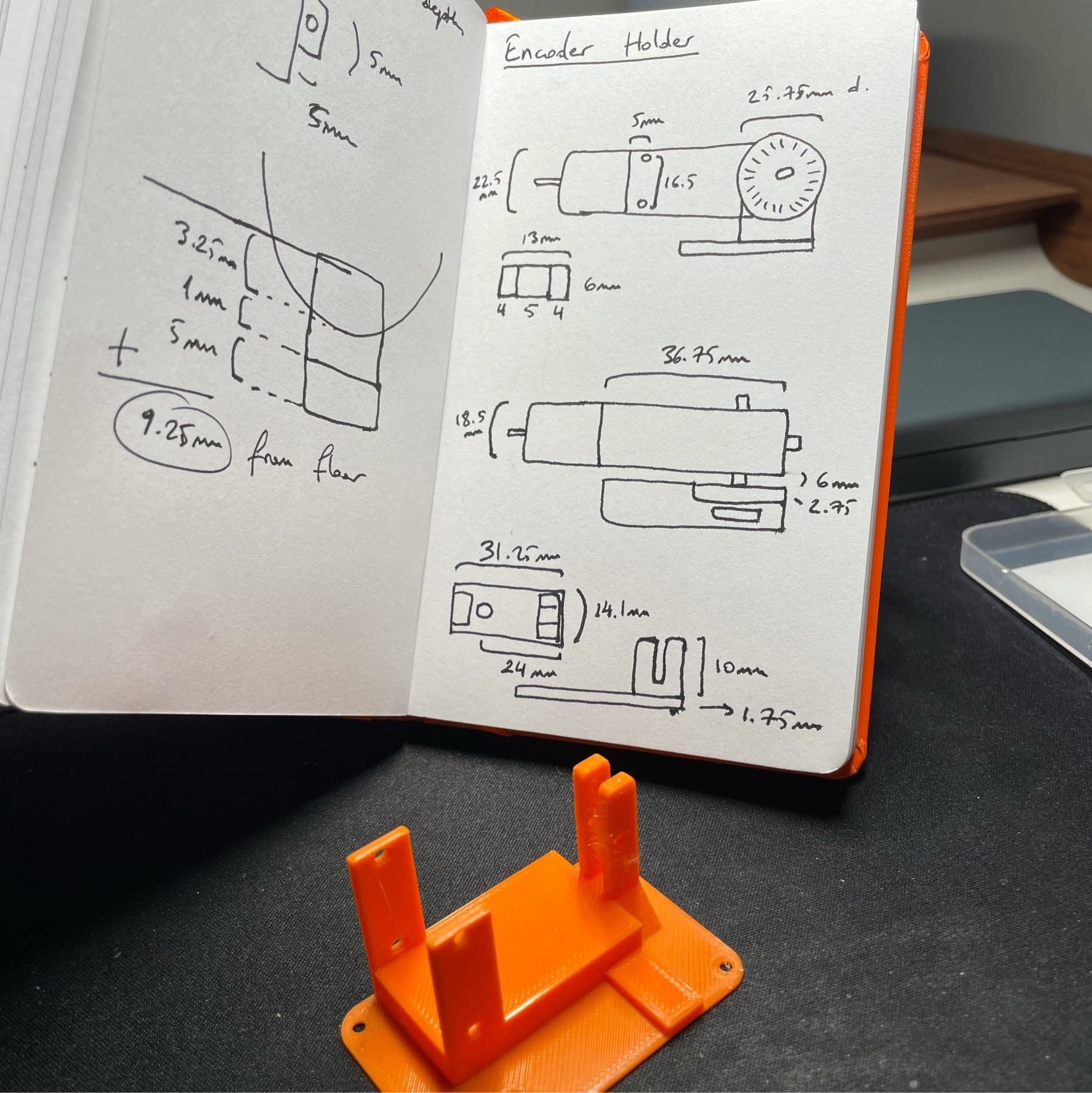

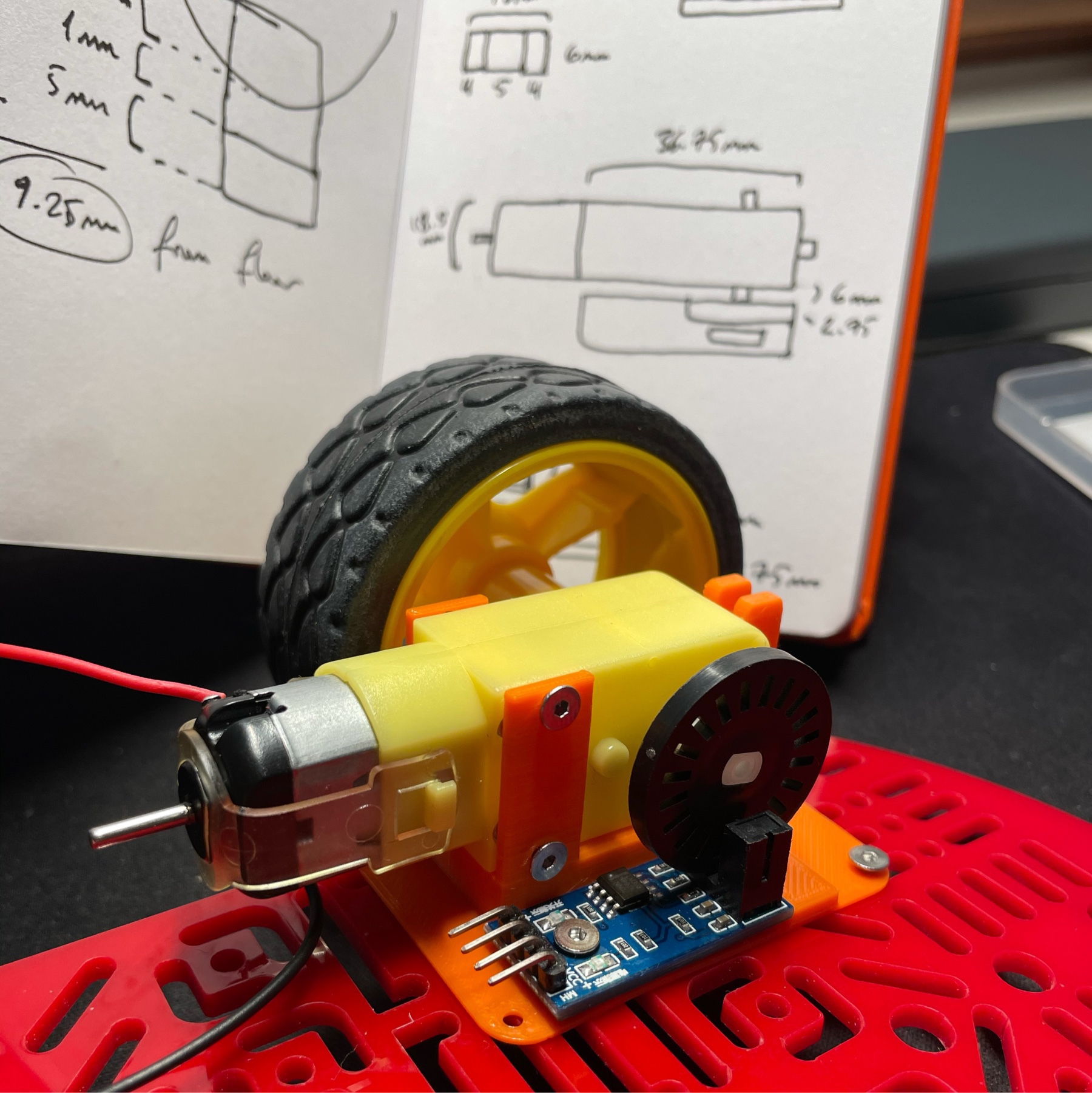

Designed and printed a motor holder for a new project I have in mind. Going to experiment with optical encoders and motors to see if I can put together a roaming bot that accurately moves in specific distances.

Flipclock digits are assembled! They are looking clean and beautiful. I will be assembling the full device tomorrow evening and hopefully have it functional.

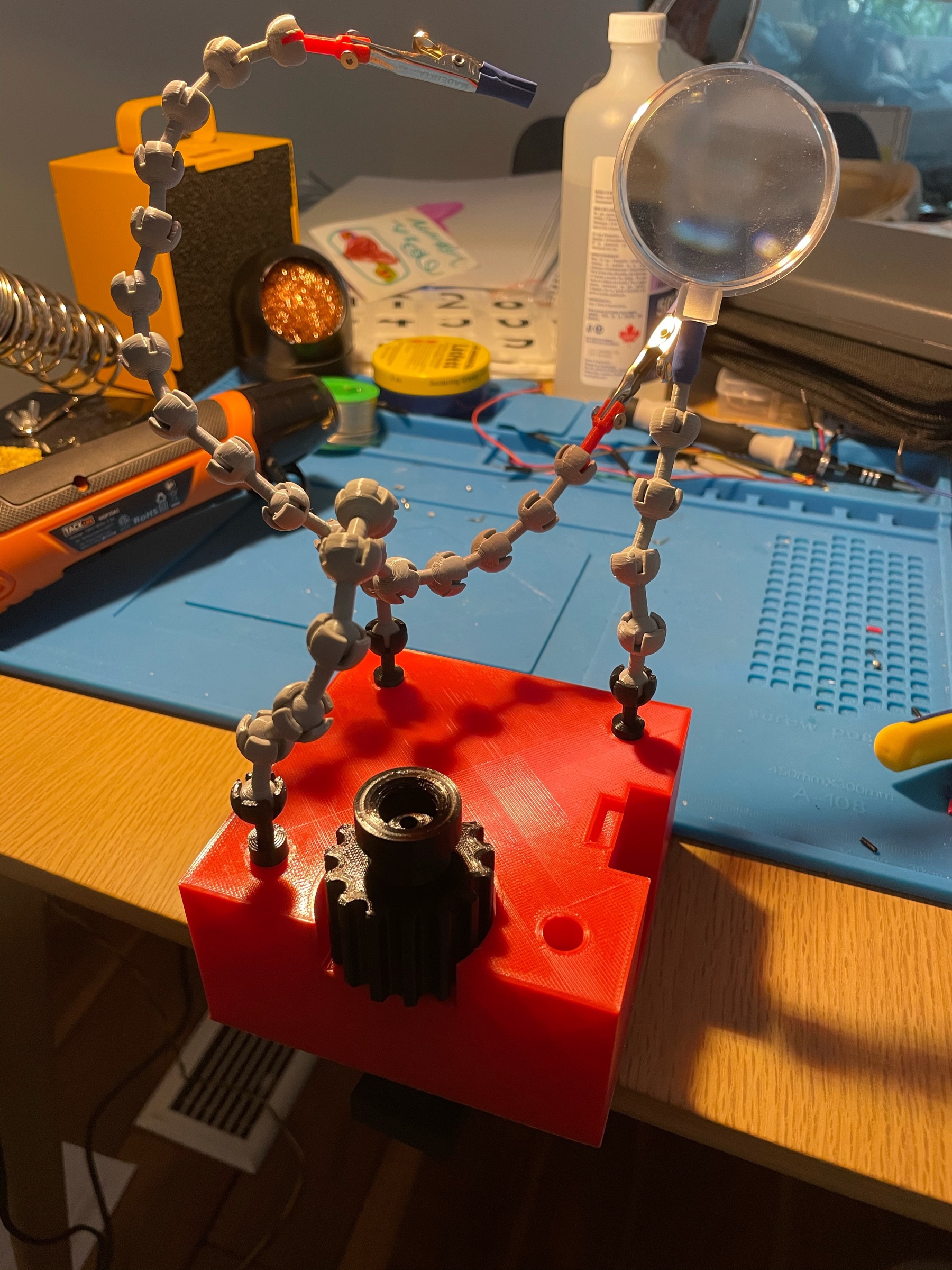

I have some soldering to do this weekend so I decided to improve my setup. After much searching, I found this design on Thingiverse. I modified the base and tips so they fit my alligator clips and can slot in without glue. Pretty happy with the results!

Started to plan out the PCB design for my handheld vacuum’s control unit. Display will show battery state and remaining operation time. Might give EAGLE a try, designing on paper can only go so far.

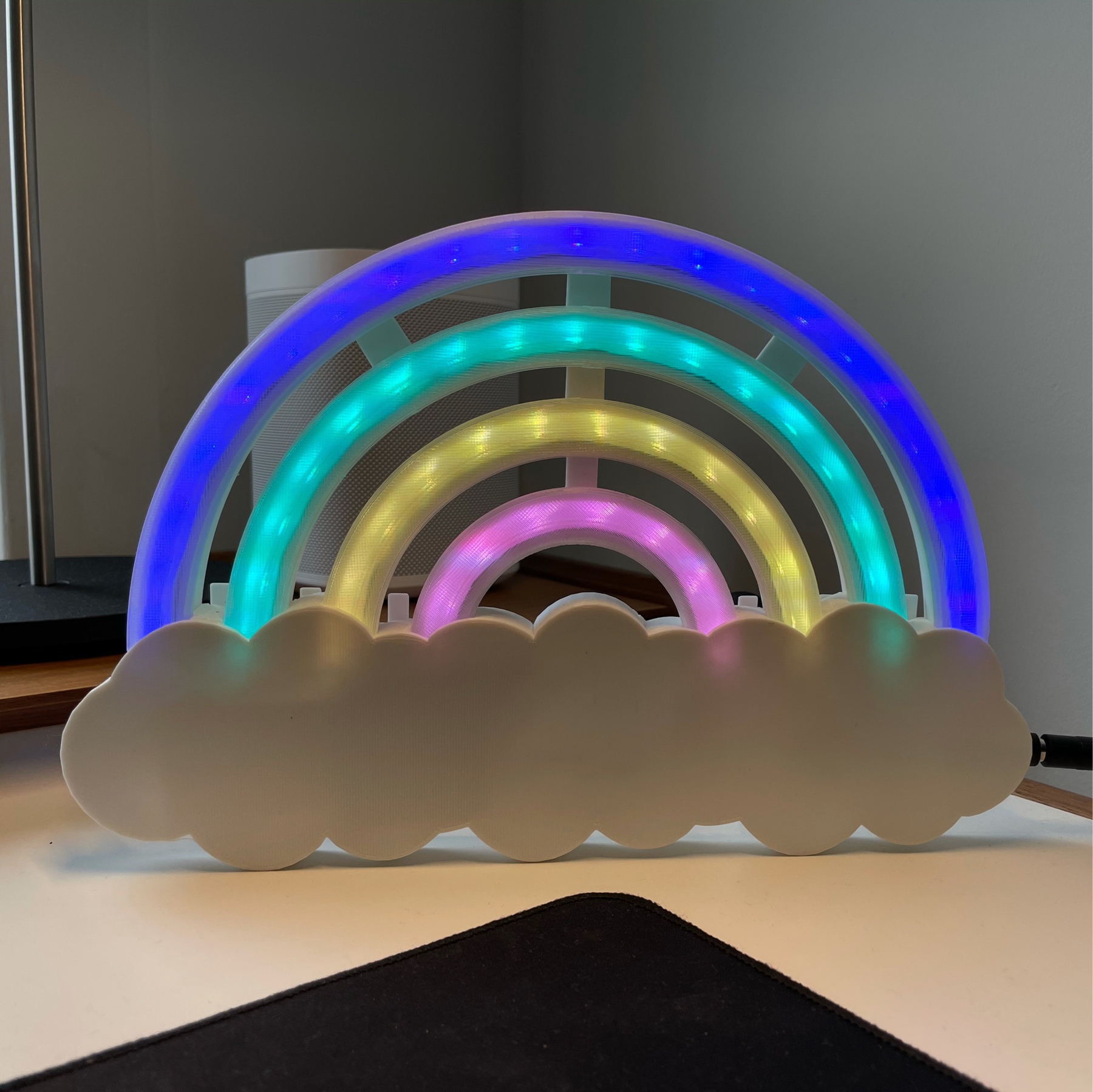

Added some logic to the LED rainbow so it dims slowly over the course of the hour before turning off for the night, and same in the morning. With that, I call this project complete!

Finally finished the LED rainbow project! After much tinkering, I gave up on the Trinket and hooked in an Arduino Nano. The memory limitations of the Trinket were being too annoying, and as I much as I like those tiny units, they are more trouble than they are worth.

Trinket Woes and A Prototyping Lesson

I also managed to get an RTC module soldered on to the LED rainbow I designed for my daughter tonight. Everything was going well until the sketch upload to the Trinket failed.

Apparently Adafruit Trinket has this issue where it’s easy to override the bootloader by mistake. I think it happened because I was using 99% of progmem.

Solution is easy, you just hook up the Trinket to another Arduino and use a little sketch to burn a fresh bootloader. Problem was: Trinket was already soldered on the prototype board!

What followed was two hours of frustrating desoldering and attaching headers.

Lesson learned: Solder headers for core components instead of soldering them directly on prototype boards. You never know when you have to get them out again.

Flipclock prototype is working well. Had to modify the front panel design and reprint, but now it’s moving smoothly. Next step is assembling the embossed digits and minute motors.

This weekend’s project: Building an old school flip clock from scratch. I based the prototype on this awesome project, but ended up redesigning the number cards. New versions are looking great with the embossed digits.